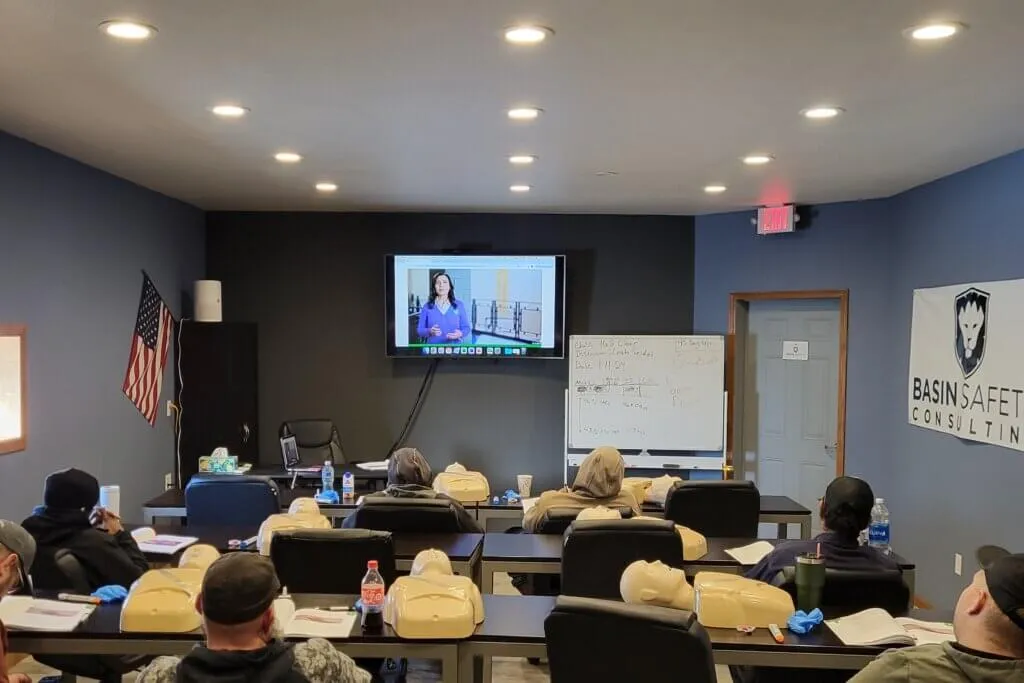

Oil Industry H2S Training Offered by Basin Safety

Our excellent Hydrogen Sulfide (H2S) safety training class offered by Basin Safety to specific oilfield industry companies, is often referred to as H2S Clear or H2S Awareness training. It will encompass several critical elements to ensure that workers are prepared to recognize, react to, and prevent H2S exposure risks. Here are the key components of our effective H2S training program:

Theoretical Training

Understanding H2S:

Properties and characteristics of H2S gas.

Sources of H2S in oil and gas operations.

Health and physical hazards associated with H2S gas.

Regulatory Standards:

OSHA, NIOSH, ANSI and other relevant guidelines and exposure limits.

Industry best practices and company-specific policies.

Detection and Monitoring:

Types and proper use of H2S monitoring and detection equipment.

Calibration and bump testing of gas detectors.

Personal Protective Equipment (PPE):

Types of respiratory protection used in H2S environments.

Selection, fit testing, use, storage, and care of PPE.

Contingency Planning:

Emergency response planning specific to H2S releases.

Evacuation procedures and muster points.

Practical Training may also be included:

Hands-On Exercises:

Real-life scenarios and role-playing exercises.

Practice using H2S detection equipment and PPE.

Emergency Response Drills:

Simulated H2S leak and evacuation drills.

Rescue and first aid procedures for H2S exposure.

Case Studies:

Review of past incidents involving H2S to learn from real events.

Safety Procedures and Best Practices

Safe Work Practices:

Job Safety Analysis (JSA) for tasks with potential H2S exposure.

Engineering controls and administrative controls to reduce risks.

Communication and Signage:

Understanding H2S warning signs and labels.

Effective communication in H2S work environments.

Decontamination and First Aid:

First aid steps for H2S exposure.

Decontamination procedures.

Assessment and Certification

Knowledge Assessment:

Written test or verbal assessment to confirm understanding of the material.

Certification:

Providing a certificate upon successful completion of the class, often a requirement for entry into H2S-prone work areas.

Continuous Improvement

Feedback Mechanism:

Opportunities for trainees to provide feedback on the course for continuous improvement.

Refresher Training:

Regularly scheduled refresher training to maintain awareness and competency.

Our comprehensive H2S Clear class is interactive, with ample opportunities for trainees to ask questions and engage with the material. It is also instructed by certified professionals with experience in hazardous environments, and the course content is regularly updated to comply with current regulations and industry standards.

Archives

Categories

Benzene Testing

Bloodborne Pathogens

Breathing Air Systems

Certification Process

Confined Space Attendants

Confined Spaces

Construction Equipment Operators

Electrical

Environmental Compliance

Excavation and Trenching

Fire Extinguisher Training

Forklift Operator

Hazcom Workplace Safety

HAZWOPER

Hearing Protection Training

Heavy Equipment

Hydrogen Sulfide

Lone Worker

Lone Worker Solutions App

Monitoring

Oil and Gas

Oil Drilling

Online Training Confined Spaces

Permit-required

PPE

Radiation Safety

Rescue Equipment

Rescue Team

Safety Consultants

Safety Devices

Safety Tracking

Safety Training

Site Inspections

Training 1

Training 2

Training 3

Training 4

Training 5

Uncategorized

Virtual Access to Safety Data

Waste Haulers

Confined Space Rescue

Mental Health

VISIT US

202 48th Ave SW, Williston, ND 58801

2740 Sims St. Suite B Dickinson, ND 58601

(701) 572-8140

BASIN SAFETY CONSULTING CORPORATION

Basin Safety believes in shared excellence. We are accountable to our core values:

● Pioneering Excellence Everyday

● Supporting each other to put customers first

● Asking the right questions, to ensure the greatest results.

Basin Safety Consulting © 2026. All rights reserved.

Powered By Upleveled Strategies

BASIN SAFETY CONSULTING CORPORATION

Basin Safety believes in shared excellence. We are accountable to our core values:

● Pioneering Excellence Everyday

● Supporting each other to put customers first

● Asking the right questions, to ensure the greatest results.

VISIT US

202 48th Ave SW, Williston, ND 58801

2740 Sims St. Suite B Dickinson, ND 58601

(701) 572-8140

Basin Safety Consulting © 2026. All rights reserved.

Powered By Upleveled Strategies